You have not bid on this auction.

BEAUTIFUL VERNEUIL BLUE SAPPHIRE TRILLION CUT 8X8X8mm 2,40ct

- SKU

- Dimensions (mm)

- x x mm

- Weight (cts)

- Certified Gemstones

- No

- Colours

-

This is a wonderful VERNEUIL SAPPHIRE...Ceylon blue color...TRillion cut 8mm, and weight 2,40cts...The best quality in VERNEUIL SAPPHIRE. THe rough come from switzerland and is the best you can find on the market, Much much better than the chinese or russian rough. Flawless.

Synthetic Ruby & Sapphire

The ability to create gemstones in the laboratory began in 1902 when Auguste Verneuil, a French chemist, developed a method known as flame fusion to create synthetic ruby. This was no mere laboratory experiment. Verneuil soon expanded his lab into a full scale production facility and was turning out 1,000 kg of synthetic corundom by 1907.

The ability to create gemstones in the laboratory began in 1902 when Auguste Verneuil, a French chemist, developed a method known as flame fusion to create synthetic ruby. This was no mere laboratory experiment. Verneuil soon expanded his lab into a full scale production facility and was turning out 1,000 kg of synthetic corundom by 1907.

Verneuil developed flame fusion primarily for the synthesis of ruby, but the same method can be used for the creation of other gem materials, including sapphire and star sapphire, spinel, rutile, and strontium titanate.

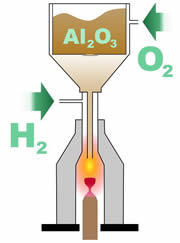

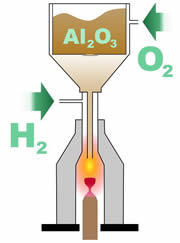

The basic concept of the flame fusion method is to take the raw gem material, melt it, and then allow it to recrystallize. The concept is simple, but this method depended on some key bits of technology. First, it was necessary to have extremely pure starting material. In the case of ruby or sapphire, this meant aluminum oxide that was free of impurities like sodium. The earliest attempts to recrystallize ruby were actually accomplished by melting natural ruby crystals, due to the lack of fine pure aluminum oxide.

Next, it was necessary to have a way to heat the powdered aluminum oxide to a temperature of at least 2,000 degree Celsius. The recently developed oxyhydrogen torch provided Verneuil with the technology for his furnace.

Next, it was necessary to have a way to heat the powdered aluminum oxide to a temperature of at least 2,000 degree Celsius. The recently developed oxyhydrogen torch provided Verneuil with the technology for his furnace.

In the Verneuil process, the powdered aluminum oxide is released down a tube where it passes through a flame that melts the material into small droplets. These droplets fall onto an earthen support rod placed at the bottom of the furnace.

The droplets form a single crystal called a boule. The boule has a characteristic shape with a rounded end, a long cylindrical body, and a tapering end. It is usually about 13 to 25 millimeters in diameter, 50 to 100 millimeters long, and weighs 75 to 250 carats.

Crystals produced by the Verneuil flame fusion process are chemically and physically equivalent to naturally occurring crystals, and strong magnification is usually required to distinguish between the two. One of the signature characteristics of a Verneuil crystal is curved growth lines formed as the cylindrical boule grows upwards in an environment with a high thermal gradient. The equivalent growth lines in natural crystals are parallel.

- SKU

- Dimensions (mm)

- x x mm

- Weight (cts)

- Certified Gemstones

- No

- Colours

-

This is a wonderful VERNEUIL SAPPHIRE...Ceylon blue color...TRillion cut 8mm, and weight 2,40cts...The best quality in VERNEUIL SAPPHIRE. THe rough come from switzerland and is the best you can find on the market, Much much better than the chinese or russian rough. Flawless.

Synthetic Ruby & Sapphire

The ability to create gemstones in the laboratory began in 1902 when Auguste Verneuil, a French chemist, developed a method known as flame fusion to create synthetic ruby. This was no mere laboratory experiment. Verneuil soon expanded his lab into a full scale production facility and was turning out 1,000 kg of synthetic corundom by 1907.

The ability to create gemstones in the laboratory began in 1902 when Auguste Verneuil, a French chemist, developed a method known as flame fusion to create synthetic ruby. This was no mere laboratory experiment. Verneuil soon expanded his lab into a full scale production facility and was turning out 1,000 kg of synthetic corundom by 1907.

Verneuil developed flame fusion primarily for the synthesis of ruby, but the same method can be used for the creation of other gem materials, including sapphire and star sapphire, spinel, rutile, and strontium titanate.

The basic concept of the flame fusion method is to take the raw gem material, melt it, and then allow it to recrystallize. The concept is simple, but this method depended on some key bits of technology. First, it was necessary to have extremely pure starting material. In the case of ruby or sapphire, this meant aluminum oxide that was free of impurities like sodium. The earliest attempts to recrystallize ruby were actually accomplished by melting natural ruby crystals, due to the lack of fine pure aluminum oxide.

Next, it was necessary to have a way to heat the powdered aluminum oxide to a temperature of at least 2,000 degree Celsius. The recently developed oxyhydrogen torch provided Verneuil with the technology for his furnace.

Next, it was necessary to have a way to heat the powdered aluminum oxide to a temperature of at least 2,000 degree Celsius. The recently developed oxyhydrogen torch provided Verneuil with the technology for his furnace.

In the Verneuil process, the powdered aluminum oxide is released down a tube where it passes through a flame that melts the material into small droplets. These droplets fall onto an earthen support rod placed at the bottom of the furnace.

The droplets form a single crystal called a boule. The boule has a characteristic shape with a rounded end, a long cylindrical body, and a tapering end. It is usually about 13 to 25 millimeters in diameter, 50 to 100 millimeters long, and weighs 75 to 250 carats.

Crystals produced by the Verneuil flame fusion process are chemically and physically equivalent to naturally occurring crystals, and strong magnification is usually required to distinguish between the two. One of the signature characteristics of a Verneuil crystal is curved growth lines formed as the cylindrical boule grows upwards in an environment with a high thermal gradient. The equivalent growth lines in natural crystals are parallel.

| Shipping provider | Shipping to France | Shipping to rest of world |

|---|---|---|

| Standard Shipping - Tracked | $8.00 / 7 days | $8.00 / 21 days |

|

France

Standard Shipping - Tracked is discounted to $10.00 on orders with 4 or more items

Rest of the world

Standard Shipping - Tracked is discounted to $10.00 on orders with 4 or more items

|

||

| Registered Shipping | $8.00 / 7 days | $8.00 / 21 days |

|

France

Registered Shipping is discounted to $8.00 on orders with 4 or more items

Rest of the world

Registered Shipping is discounted to $8.00 on orders with 4 or more items

|

||

-

Positive

PositiveHighly respected, trusted service, excellent specimens, great value. Hoch angesehenen und vertrauenswürdigen service, hervorragende exemplare, groben wert. Hautement respecté, service confiance, excellents spécimens de grande valeur. Merci Beaucoup

-

Positive

PositiveReally beautiful rough, looking forward toward the next rough.

-

Positive

PositivePaid and shipped - no feedback left after 100 days

-

Positive

PositivePaid and shipped - no feedback left after 100 days

-

Positive

PositivePaid and shipped - no feedback left after 100 days

-

Positive

PositivePaid and shipped - no feedback left after 100 days

Why are users outbidding themselves?

When a bid is placed, this is the maximum amount a user is willing to bid for the product. Our system will then automatically bid on that users behalf, incrementally increasing the bid to maintain their position as the highest bidder, up to the specified maximum.

When there is an icon indicating 'Auto Bid,' it means our system is actively placing bids for the user based on their maximum bid. This may appear as if users are outbidding themselves, but it's simply a result of the system updating the bid to reflect the users maximum limit.